Article |

Unit |

MICOS 37 |

MICOS 55 |

MICOS 75 |

MICOS 110 |

MICOS 150 |

|

Compression method |

Oil flooded, 1-stage compression |

||||||

Capacity(F.A.D)(1) |

7bar |

㎥/min |

6.67 |

10.30 |

13.73 |

21.20 |

28.53 |

9bar |

6.11 |

9.12 |

13.10 |

18.60 |

26.16 |

||

12bar |

4.58 |

7.10 |

9.83 |

16.10 |

23.07 |

||

Compression unit |

Driven method |

Direct coupled drive |

|||||

Suction Temperature(3) |

℃ |

MAX. 40 |

|||||

Outlet Temperature |

MAX. suction temperature+15 |

||||||

Cooling method |

Air cooled / Water cooled |

||||||

Motors |

Rated power |

KW |

37 |

55 |

75 |

110 |

150 |

Input Voltage |

V |

AC 220 / 380 / 440, 3-phase |

|||||

Frequency |

Hz |

50 / 60 |

|||||

Starting method |

Y-△ |

Y-△ / REACTOR / SOFT STARTER |

|||||

Pipe connection |

32A |

50A |

65A |

||||

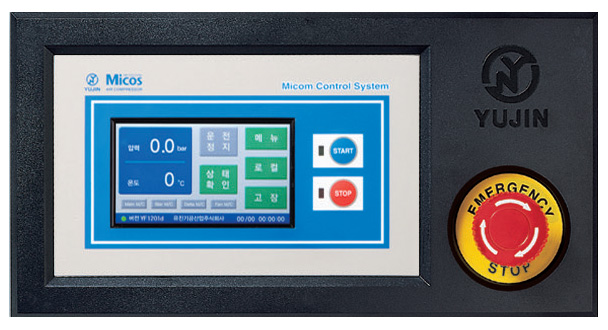

Control method |

Load/Unload control(by MICOS-Ⅳ controller) |

||||||

Noise leve(2) |

dB(A) |

68 |

70 |

71 |

73 |

76 |

|

Weight |

kg |

1,100 |

1,550 |

1,800 |

2,900 |

3,300 |

|

Overall dimension(L x B x H) |

mm |

1,700×1,065×1,500 |

1,900×1,330×1,750 |

2,482×1,800×1,960 |

2,482×1,800×1,960 |

||

(1) According to ISO1217 Edition3-1966, Annex-C

(2) According to ISO2151 Edition1-1972

(3) High temperature packages upto 55℃ are available

Article |

Unit |

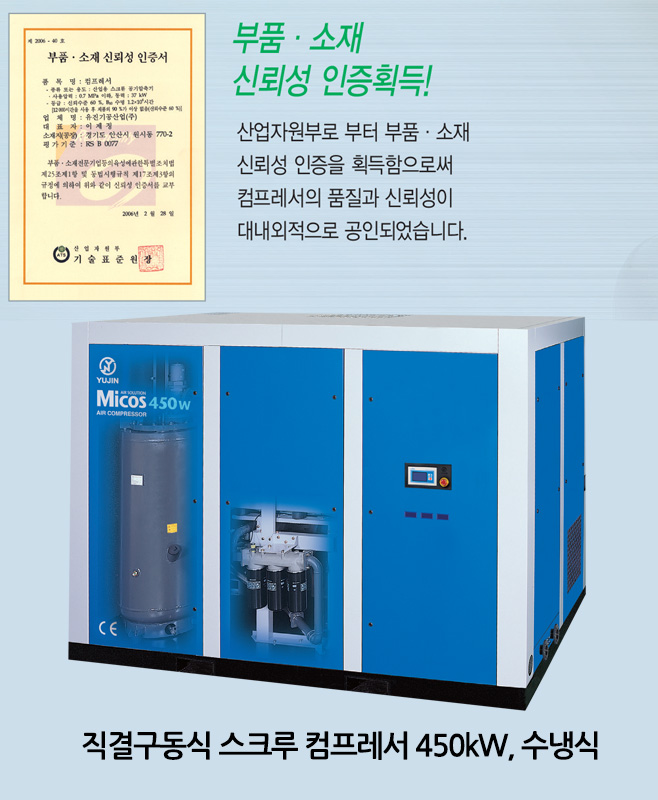

MICOS 190 |

MICOS 225 |

MICOS 260 |

MICOS 300 |

MICOS 375 |

MICOS 450 |

|

Compression method |

Oil flooded, 1-stage compression |

|||||||

Capacity(F.A.D)(1) |

7bar |

㎥/min |

35.0 |

40.6 |

45.8 |

55.3 |

73.1 |

78.6 |

9bar |

30.0 |

33.3 |

38.2 |

50.2 |

61.3 |

72.1 |

||

12bar |

26.8 |

29.6 |

31.9 |

45.0 |

53.2 |

58.2 |

||

Compression unit |

Driven method |

Direct coupled drive |

||||||

Suction Temperature(3) |

℃ |

MAX. 40 |

||||||

Outlet Temperature |

MAX. suction temperature+15 |

|||||||

Cooling method |

Air cooled / Water cooled |

ater cooled |

||||||

Motors |

Rated power |

KW |

190 |

225 |

260 |

300 |

370 |

445 |

Input Voltage |

V |

AC 220 / 380 / 440, 3-phase (AC 400 / 415 / 460, AC 3,300 / 6,600 : option) |

||||||

Frequency |

Hz |

50 / 60 |

||||||

Starting method |

Y-△ / REACTOR / SOFT STARTER |

REACTOR / SOFT STARTER |

||||||

Pipe connection |

80A |

100A |

125A |

|||||

Control method |

Load/Unload control(by MICOS-Ⅳ controller) |

|||||||

Noise leve(2) |

dB(A) |

78 |

79 |

81 |

83 |

85 |

85 |

|

Weight |

kg |

4,800 |

5,530 |

6,420 |

7,320 |

7,900 |

8,900 |

|

Overall dimension(L x B x H) |

mm |

3,382×2,100×2,500 |

3,582×2,100×2,525 |

|||||

(1) According to ISO1217 Edition3-1966, Annex-C

(2) According to ISO2151 Edition1-1972

(3) High temperature packages upto 55℃ are available