Article |

Unit |

AIRTEC 22V |

AIRTEC 37V |

AIRTEC 75V |

|||

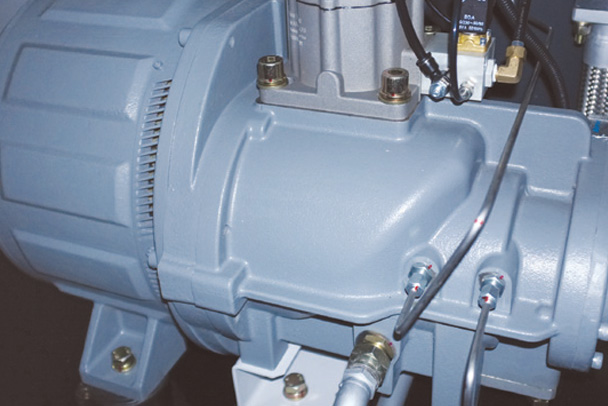

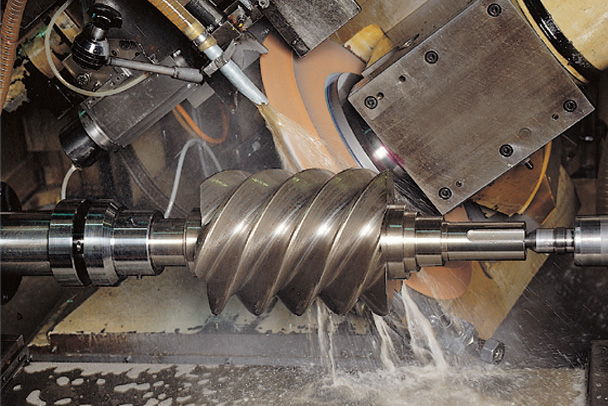

Compression method |

Oil-fed screw one-stage compression method

|

||||||

Capacity(F.A.D)(1) |

7bar |

㎥/min |

1.1~3.8 |

2.0~6.7 |

4.10~13.2 |

||

8.5 bar |

1.0~3.3 |

1.9~6.4 |

3.7~12.2 |

||||

Compression unit |

Driven method |

Direct drive method

|

|||||

Suction Temperature(3) |

℃ |

MAX. 40 |

|||||

Outlet Temperature |

MAX. suction temperature +15 |

||||||

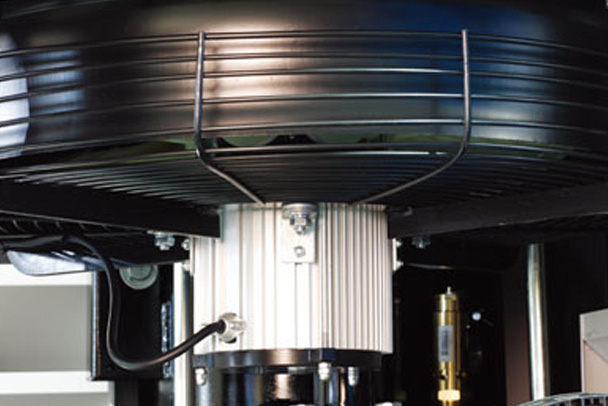

Cooling method |

Air cooled |

||||||

Motors |

Rated power |

KW |

22 |

37 |

75 |

||

Input Voltage |

V |

AC 220 / 380 / 440V, 3-phase |

|||||

Frequency |

Hz |

60 |

|||||

Starting method |

Soft start by Inverter(No peak current) |

||||||

Pipe connection |

20A |

40A |

50A |

||||

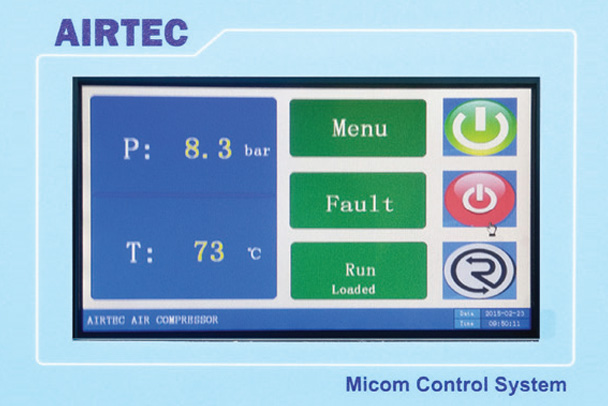

control method |

Airtec-3 mycom control |

||||||

Noise level(2) |

dB(A) |

70 |

71 |

74 |

|||

Weight |

kg |

450 |

600 |

1,800 |

|||

size(L x B x H) |

mm |

1,100×826×1,305 |

1,200×872×1,465 |

1,650×1,166×1,762 |

|||

(1) According to ISO1217 Edition3-1966, Annex-C

(2) According to ISO2151 Edition1-1972