Article |

Unit |

MICOS 55F |

MICOS 75F |

MICOS 90F |

MICOS 110F |

MICOS 132F |

MICOS 160F |

MICOS 190F |

MICOS 225F |

MICOS 260F |

|

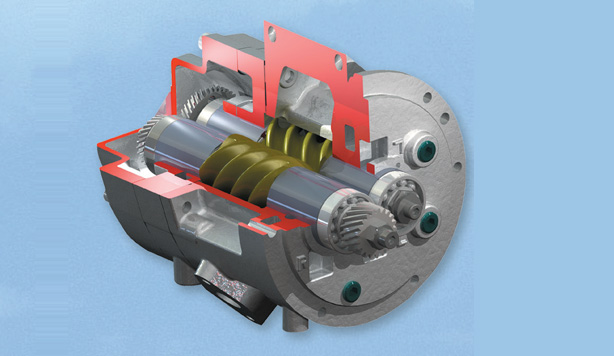

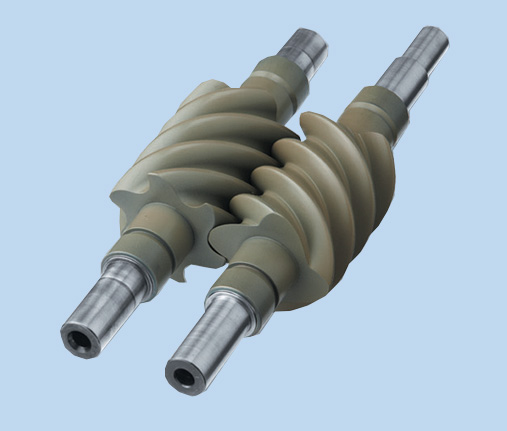

Compression method |

- |

Oil-fed, single-stage screw compression method

|

|||||||||

Capacity (F.A.D)(1) |

7bar |

㎥/min |

8.2 |

12.7 |

15.0 |

18.7 |

22.6 |

27.0 |

31.6 |

39.5 |

46.0 |

8.5 bar |

8.1 |

10.6 |

12.7 |

16.7 |

18.6 |

21.8 |

27.8 |

32.0 |

39.4 |

||

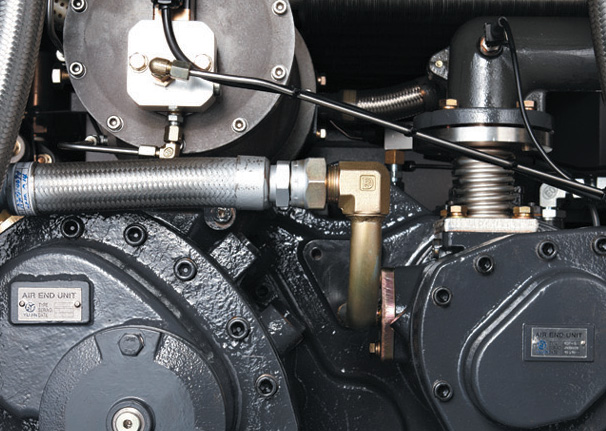

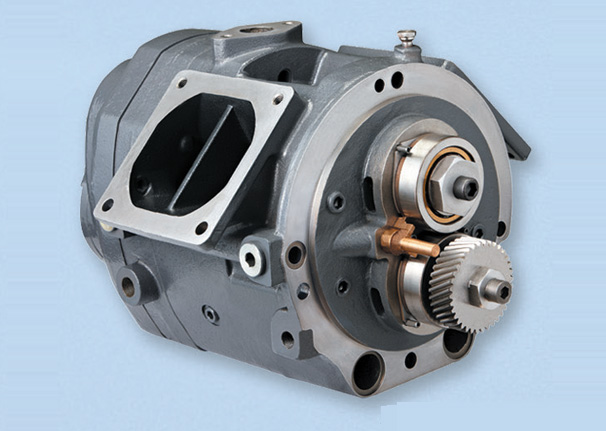

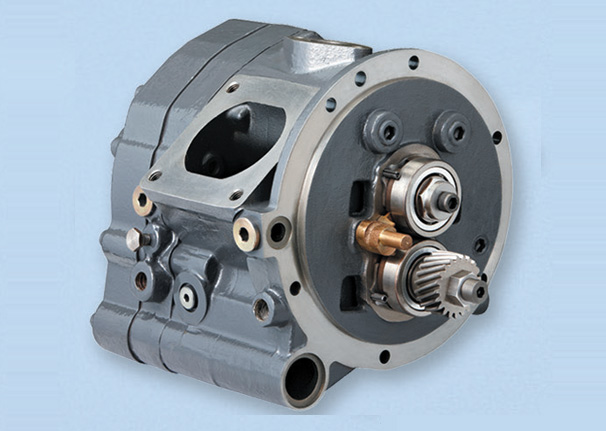

Compression unit |

Driven method |

Direct drive method

(Gear driven) |

|||||||||

Suction Temperature(3) |

℃ |

MAX. 40 |

|||||||||

Outlet Temperature |

MAX. suction temperature +15 |

||||||||||

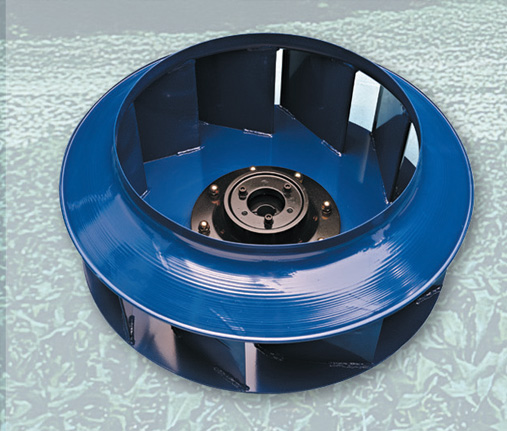

Cooling method |

Air cooled / Water cooled |

||||||||||

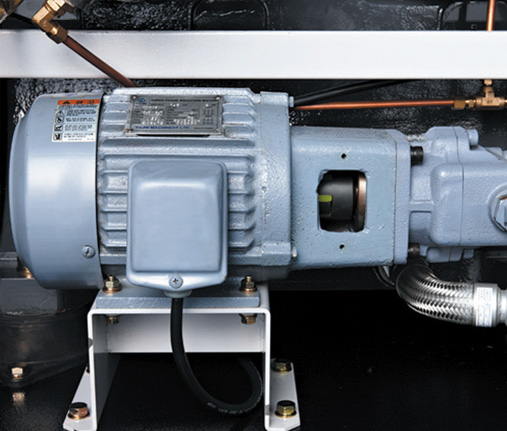

Motors |

Rated power |

KW |

55 |

75 |

90 |

110 |

132 |

160 |

190 |

225 |

260 |

Input Voltage |

V |

AC 220 / 380 / 440, 3-phase (Option : AC 400 / 415 / 460, AC 3.3 / 6.6 kV) |

|||||||||

Frequency |

Hz |

50 / 60 |

|||||||||

Starting method |

Y-△ Starting method / Reactor / Soft Starter |

||||||||||

Pipe connection |

50A |

65A |

80A |

||||||||

Control method (IN / OUT) |

50A |

50A |

80A |

||||||||

control method

|

Micos-2F mycom control

|

||||||||||

Noise level(2) |

Air cooled |

dB(A) |

81 |

82 |

83 |

83 |

84 |

86 |

- |

- |

- |

Water cooled |

dB(A) |

78 |

80 |

81 |

82 |

83 |

84 |

85 |

86 |

88 |

|

Weight |

Air cooled |

kg |

2,440 |

2,500 |

2,600 |

3,710 |

3,800 |

3,860 |

- |

- |

- |

Water cooled |

kg |

2,480 |

2,540 |

2,870 |

3,650 |

3,730 |

3,800 |

4,950 |

5,550 |

6,300 |

|

size

(L×B×H) |

Air cooled |

mm |

2.070×1,360×2,040 |

2.580×1,750×2,250 |

- |

- |

- |

||||

Water cooled |

mm |

2.150×1,420×1,800 |

2.630×1,700×1,830 |

3,270×1,700×1,950 |

|||||||

(1) According to ISO1217 Edition3-1966, Annex-C

(2) According to ISO2151 Edition1-1972

Article |

Unit |

MICOS 75Fv |

MICOS 90Fv |

MICOS 160Fv |

MICOS 260Fv |

|

Compression method |

- |

Oil-free screw two-stage compression method

|

||||

Capacity (F.A.D)(1) |

7bar |

㎥/min |

6.3~12.7 |

6.9~15.0 |

12.1~27.0 |

20.0~46.0 |

8.5 bar |

6.3~11.1 |

6.0~12.9 |

12.1~22.3 |

20.0~39.4 |

||

Compression unit |

Driven method |

Direct drive method(Gear driven) |

||||

Suction Temperature(3) |

℃ |

MAX. 40 |

||||

Outlet Temperature |

MAX. suction temperature+ 15 |

|||||

Cooling method |

Air cooled / Water cooled |

|||||

Motor |

Rated power |

KW |

75 |

90 |

160 |

260 |

Input Voltage |

V |

AC220 / 380 / 440, 3-phase (Option : AC 400 / 415 / 460, AC 3.3 / 6.6 kV) |

||||

Frequency |

Hz |

50 / 60 |

||||

Starting method |

Soft start by Inverter (No peak current) |

|||||

Pipe connection |

50A |

65A |

80A |

|||

Control method (IN / OUT) |

50A |

50A |

80A |

|||

control method |

Micos-2F mycom control

|

|||||

Noise level(2) |

Air cooled |

dB(A) |

82 |

83 |

86 |

- |

Water cooled |

dB(A) |

80 |

81 |

84 |

87 |

|

Weight |

Air cooled |

kg |

2,620 |

2,500 |

3,900 |

- |

Water cooled |

kg |

2,680 |

2,810 |

3,850 |

6,500 |

|

size (L×B×H) |

Air cooled |

mm |

2.260×1,430×2,040 |

2,560×1,750×2,250 |

- |

|

Water cooled |

mm |

2.150×1,420×1,800 |

2.630×1,700×1,830 |

3,270×1,700×1,950 |

||

(1) According to ISO1217 Edition3-1966, Annex-C

(2) According to ISO2151 Edition1-1972